How To Help Businesses

Make safety management an indicator of the entire ESG solution.

Why has safety become an important indicator for a company’s sustainable management? Herbert William Heinrich, a famous American scholar, studied the insurance industry's occupational accident claims database and obtained the classic ratio of 88:10:2, that is, 88% of accidents were caused by "unsafe behaviors", 10% were caused by "unsafe conditions", and 2% were caused by "unpreventable factors." These include the Qingdao oil pipeline explosion in November 2013, the Kaohsiung gas explosion in July 2014, and the Suzhou Kunshan Zhongrong Metal Explosion in August 2014, which can be described as "black swan events"; they were caused by poor design (safety built-in), insufficient inspection (safety confirmation), and insufficient safety awareness training for personnel (risk assessment and accident investigation), and most of these were avoidable.

In other words, safety factors are not only detected through inspection, but also through implementation (execution), design (PtD), management (TOSHMS), and leadership/participation.

"Safety management system"and"technology application" are highly relevant to the social responsibility aspect of ESG. Companies need to view these workplace safety management practices as concrete measures to fulfill their social responsibilities, protect the health and safety of their employees, and improve operational efficiency. They should also further incorporate these actions into ESG reports to demonstrate their efforts in sustainable development.

Design Concept

Combine mobile devices

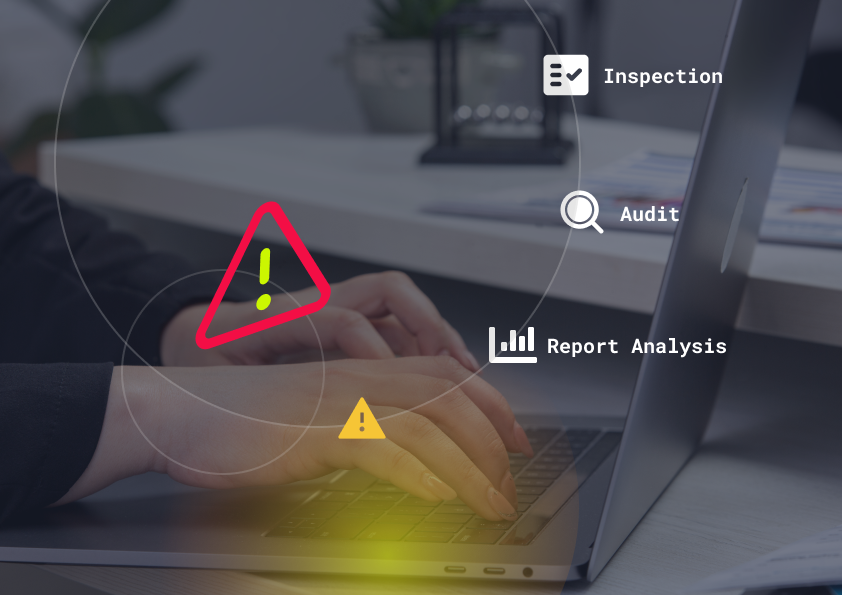

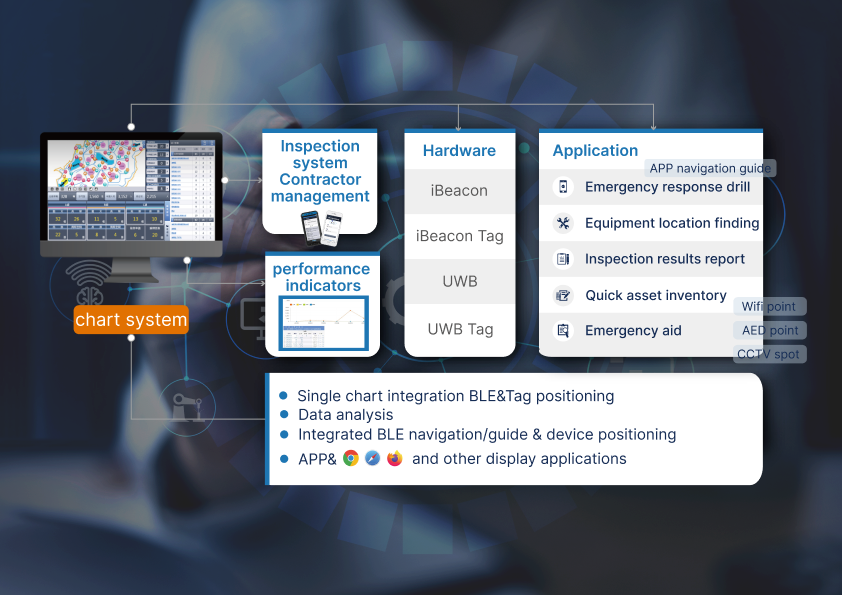

Our company's related software development focuses on safety design and combines a number of mobile device innovation technologies to build inspection and audit systems for various sites, items, and equipment, and proactively sends abnormal message notifications in real time through mobile vehicles and information technology. and other mechanisms to improve managers understanding and management of high-risk operations on site.

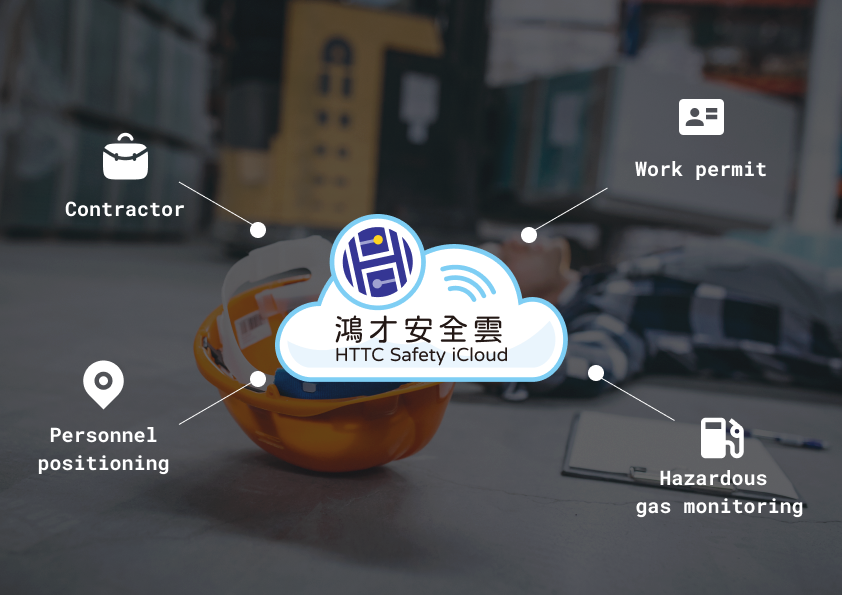

Using Hon-Tsai Security IoT Cloud

Enterprises can use technology (Hon-Tsai Safety IoT Cloud) to strengthen industrial safety management, reduce industrial safety accidents, and protect employee health. Through systematic data analysis, we continuously improve the results of workplace safety management, use data to drive decision-making, fulfill our responsibilities to society and employees, and formulate more complete ESG strategies to contribute to sustainable development.

System Overview

Product Description

Prevention and control of industrial accidents

- Emphasize the prevention and control of industrial accidents. Through the "Hongcai Safety IoT Cloud" system, companies can better manage contractors, work permits, personnel positioning and hazardous gas monitoring, thereby reducing the risk of industrial safety accidents. This is directly related to social responsibility in ESG, especially employee health and safety.

Data analysis and decision making

- The Hon-Tsai Technology System can provide information such as statistics on work safety deficiencies, annual disaster inquiries, and generate decision-making reports. This means that companies can manage workplace safety based on data and make continuous improvements. Such data-based management and continuous improvement are also in line with ESG requirements.

Technology Application and Innovation

- Utilize technologies such as wireless transmission, mobile devices and data platforms to improve the efficiency and effectiveness of industrial safety management. Assisting enterprises in pursuing excellence and sustainable development is related to the innovation aspect of ESG.

System Integration

- The Hon-Tsai IoT safety network system can integrate data from different systems such as PSM, CMMS, AIMS, and ERP, helping companies to have a more comprehensive understanding of workplace safety conditions and incorporate them into overall operational management. It can be seen as a practice of corporate governance.