How To Help Businesses

Improve Safety Management to Mobile Operational Audit.

Companies have long been investing resources in the prevention of safety incidents by organizing education and training, reinforcing good practice of safety and health regulations, and performing quality assurance audit. The government authorities and business operators in the construction industry, for this reason, have continued to implement labor safety and health-related regulations and audits, including promoting the occupational disaster posters and other strategies, so that all construction projects in the country have “zero incident and zero fatality”. Although it is unlikely for every major project to completely avoid incidents, it is hardly in the business operator’s interest to neglect the impact of accident on the company. Therefore, whether it is done by autonomous management or reinforced by the competent authorities, or simply because of the benevolent heart to respect the life and safety of each worker, the construction companies will face the absolute pressure to enforce the implementation of the safety policy and system.

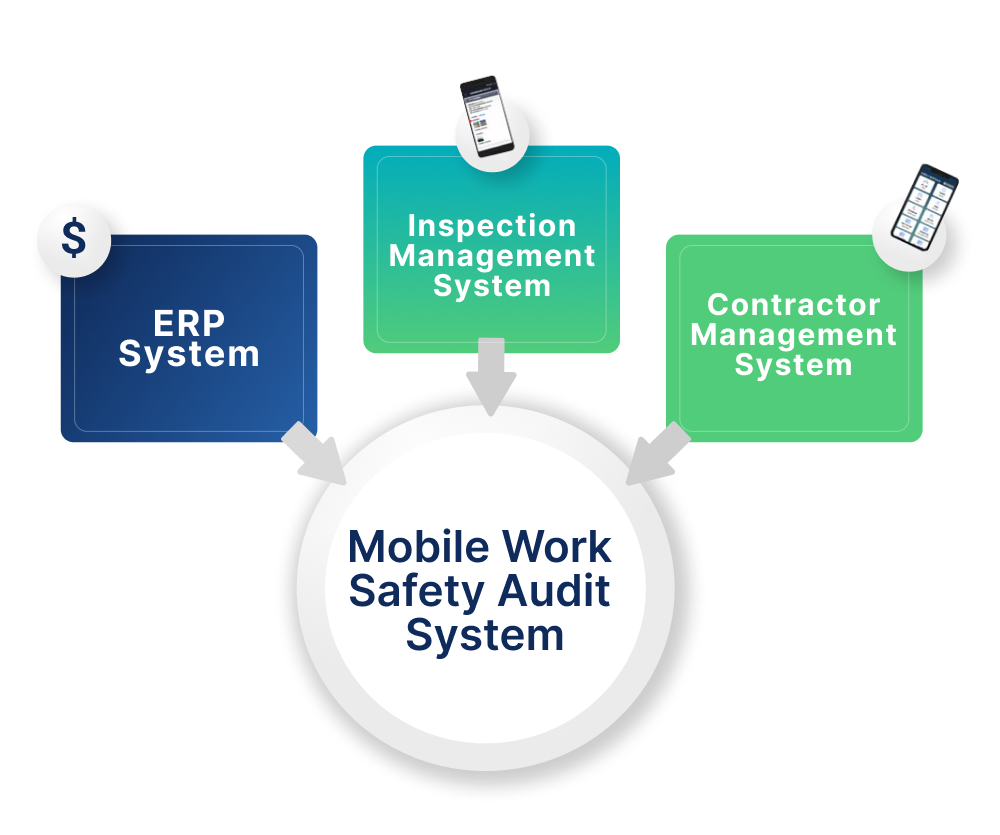

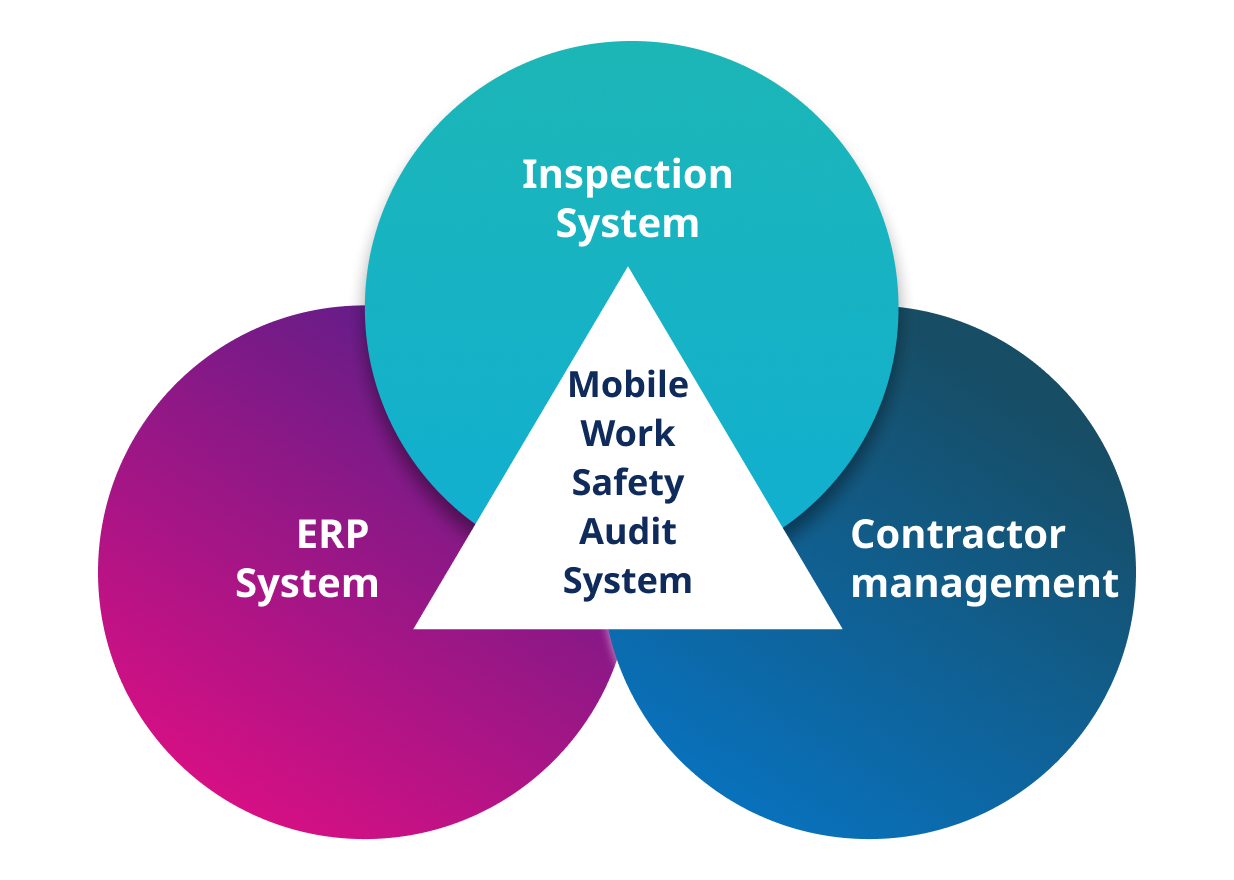

The mobile environmental safety management system, including both the front- and back-end software, is developed solely by Hon-Tsai Technology and patented for its mobile industrial safety inspection system and method, the personnel in-positioning system, the smart inspection expert knowledge base system, and other proprietary products. The entire system covers key functions such as environmental management, incident statistics, work safety audit, improvement tracking, autonomous site inspection, etc. Using the mobile environmental safety management system, it provides updates on the list of key inspection items based on the latest labor and safety regulations for construction site (or factory) operation; assists in managing the work environment, task operation and autonomous inspection for on-site workers; or provides functions of daily site inspection, task assignment, and improvement tracking for supervisors, not to mention, it also notifies the incidents, provides annual statistics of incidents, analyzes the statistics of work safety issues, prepares details on incidents of the year, investigates the false alarm events, and compiles decision report, all of which are part of crucial information for the corporate management.

Mobile Safety Inspection System and App, which can assist businesses in 'identifying issues, promptly reporting, swift improvement, and tracking compliance,' is the best way to reduce crises.

Design Concept

Audit report

When the auditor finds a problem,they need to immediately submit an inspection report and provide recommendations of action to the corporate management. The system can be regarded as an important communication tool for both parties.The report should disclose facts that have come to light,but does not distort or tamper with the information that may lead the company to violate any regulations.

Master the missing information of safety equipment personnel

This allows the corporate management to handle the improvement operation immediately based on the information provided from inspection, which shall avoid any losses in properties or lives due to the occupational hazard caused by autonomos management on site and thus,effectively improve the standard of management in construction work safety.

Smart mobile audit system

Smart phones and tables have bacome an importamt part and way of transmitting information by the public.Owing to its convenience,the work style is taling a new turn, as auditor and corporate management will be satisfied of their needs for faster bilateral communication and immediate notification of warning through the use of our company's smart mobile auditimg system.

System Overview

Contractor

- Spot unit and supplier rating.

- E-matching of inspection deficiency.

- Defining the inspector.

Management

- Statistical analysis of yearly disaster events.

- Analytical report on disaster investigations.

- Disaster notification.

- Occupational deficiency statistics and analysis.

- Annual number of disaster.

- Inquiry of near-miss events.

- Decision report.

Operactor

- Control of the spot operating environment.

- Mission operating management.

- Automatic inspection management.

Every construction/factory project

- Occupational regulation management renewal.

- Inspection item renewal.

Report

- Statistical chart for inspection.

- Statistical and analysis chart of occupational office safety inspection for labor safety in construction.

- Inspection deficiency items

- Inspection type inquiry statement.

- Inspection object inquiry statement.

- Notice form for construction quality inspection.

- Regular occupational safety inspectional safety inspection.

- Type of integrated construction deficiency.

- Monthly report submitted to the Qccupational Safety Office.

- Inspection results feom the Occupational Safety Office and Labor Inspection Office Satistics of memo sending.

Every construction site supervisor

- Daily construction site inspection.

- Deficiency improvement allocation.

- Violation/extraordinary improvement tracking.

The information of work safety inspection is always in real time and the personnel in charge will be notified immediately and directly on the front-end device, so that the improvement operation may start as soon as possible to reduce the impact on cost, time delay, reputation, etc.

Provided that the business operator may instantly inquire about various work safety issues and reports on the improvement operations through the Internet, the system will also use the relevant data to generate reports on the company’s performance in work safety.

The system will establish a notification mechanism for returning the status of violation/exception/improvement on site in accordance with the current three-level industrial safety audit regulations (involving the labor safety inspection unit, the business operator or its supervisory unit, and the head office, construction site or the factory) and ISO 45001 internal and external audit standard.

The auditing process and report are done in one operation to reduce the time to organize documentation, which are all linked for the corporate management to inquire instantly. And there is the benefit of data integration and reusability to reduce the chance of negligence during inspection operations.

The audit results are immediately notified to the company, which will be verified and signed off by superior management level by level. All results can be printed into report or as a memorandum to remind the supplier.

The system provides multiple real-time notification methods to tightly control the schedule of improvement operation. It will also notify with warning message through E-mail, APP or instant communication like LINE for any operation exceeding the deadline.

Product Description

Application Level

Personal protective equipment inspection, first aid kit inspection, general safety inspection, general vehicle safety inspection, construction vehicle & machinery safety inspection, electrical safety inspection, mobile crane operation safety inspection, fixed crane operation safety inspection, concrete casting safety inspection, formwork safety inspection, automatic oxy‑acetylene operation safety inspection, hoisting operation safety inspection, scaffolding safety inspection, steel construction safety inspection, open pit excavation safety inspection, soil-retaining & supporting operation safety inspection, diaphragm wall safety inspection, reversed circulation cast-in-place pile safety inspection, construction elevator safety inspection, autonomous excavation safety inspection, winding apparatus safety inspection, excavator operation safety inspection, reinforced disaster safety inspection, working platform safety inspection, confined space operation safety inspection, annual inspection of oxy-acetylene welding device, daily pre-work inspection of stacker, crane safety inspection, oxy-acetylene equipment safety inspection, daily safety & hygiene inspection, and scaffold structure safety inspection.

Autonomous inspection of construction site, sporadic engineering project audit, fire safety equipment inspection, environment/toilet tidiness audit, food court and store audit, internal quality audit, external quality audit, three-level industrial safety audit, security duty audit...

The audit will inspect raw materials, semi-finished products, finished products, quality-related documents, personnel and their activities in workplaces such as the construction office on site, construction premises, material processing area, and processed material storage area. As for the audit on workmanship, this will inspect the quality of steel structure, steel bar, formwork, grouting, piping, structural waterproofing, ceiling decoration, floor tiling, partition wall, wall surface, doors, and windows...

Construction Site Safety Audit Management

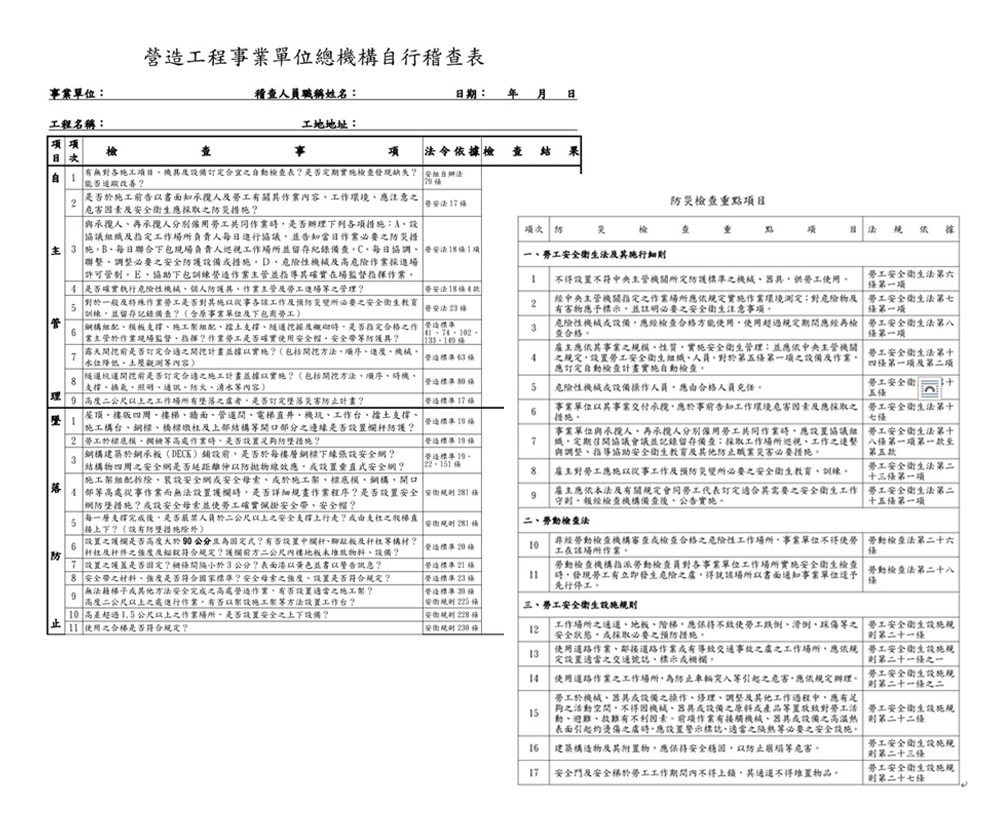

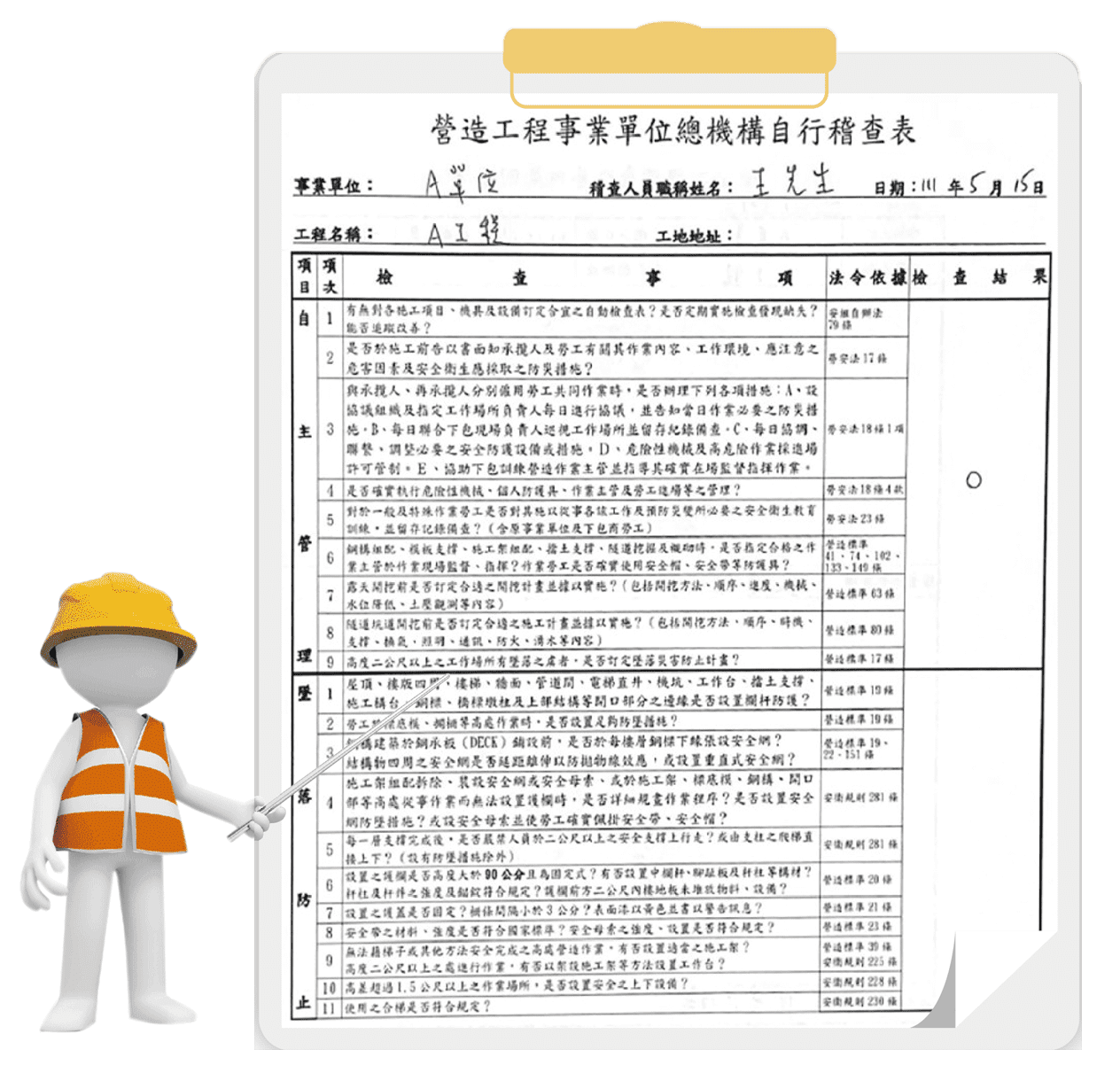

Traditional Operations: In the construction industry, various audit forms are used to comply with the content of occupational safety and health management regulations. How do you manage them? Do you fill them out on paper? Scan and archive them? Input data into purely electronic forms? Is it challenging to retrieve the data when needed?

Zero accidents, zero fatalities

Electronic data storage and information

Implementing improvements based on deficiencies

Actionable reporting for improvements

The system's back end provides an easy-to-use interface for clients to manage essential contractor data independently. This includes site supervisors, occupational safety personnel, approved subcontractor companies, entry personnel, occupational safety certifications, and safety education training.

It offers a comprehensive solution for managing non-compliance incidents, integrating them into the PDCA (Plan-Do-Check-Act) management cycle. For instance, users can capture photos of deficiencies and improvements using mobile devices like tablets and smartphones, digitize and upload the data, and send notifications to relevant supervisors.

The system combines three levels of occupational safety audits (labor inspection authorities/employers, supervisory units/head offices, and construction sites or factory ends) with ISO 45001 standards. This establishes a mobile reporting system for non-compliance, anomalies, and improvements.

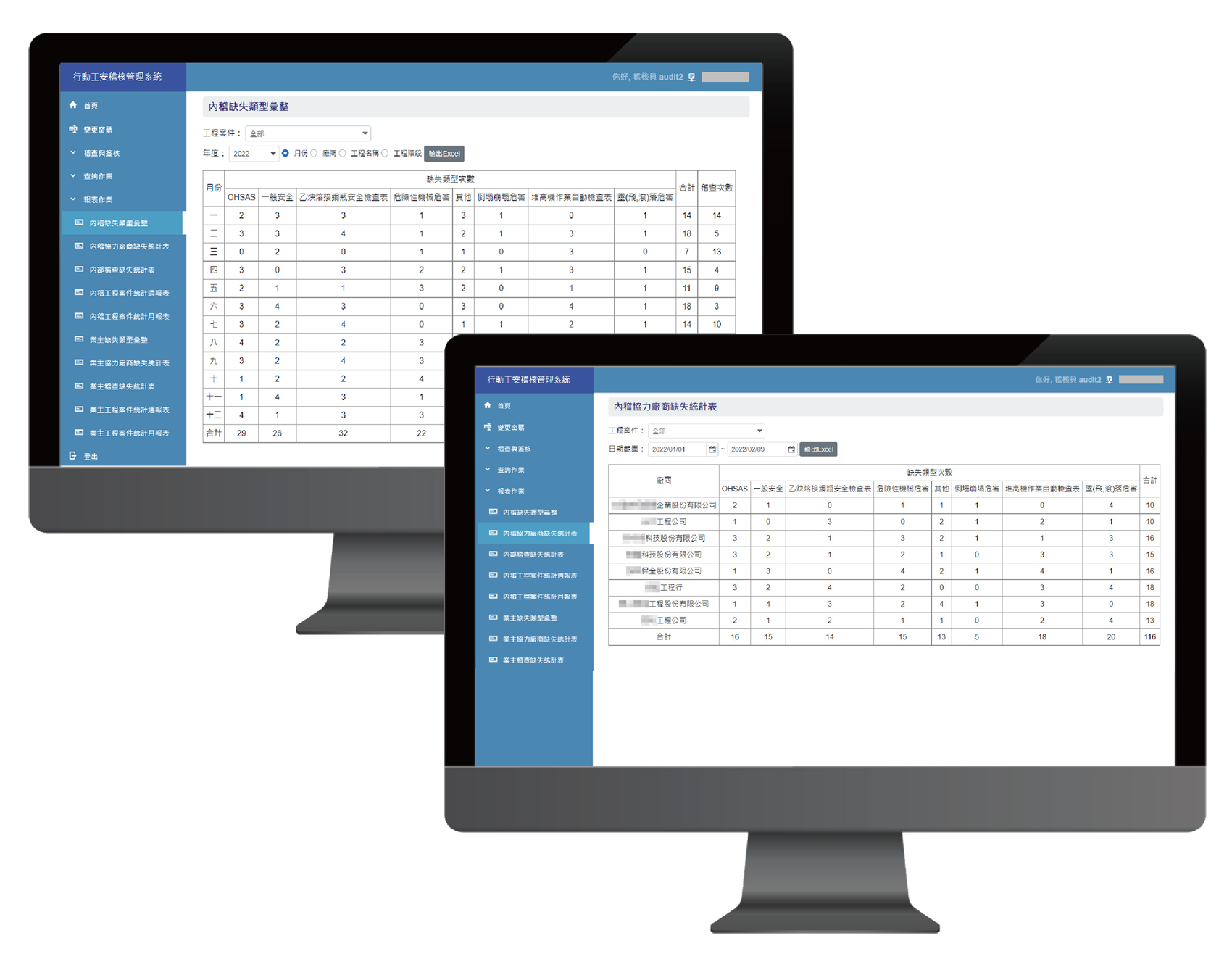

The platform lets clients access various safety deficiency and improvement reports online. Users can apply this information to create company safety performance indicator reports, covering aspects such as ISO 45001 internal audits, annual disaster incident statistics and analysis, safety deficiency statistics, and more.

- User-Friendly Operation: Easily generate comprehensive audit reports in one go using the digital handheld front end app, eliminating the need for time-consuming data consolidation via computers.

- Precise Data Management: Combine digital dashboards to thoroughly understand deficiency types and quantities among various contractors, focusing on targeted improvements.

- Real-Time Notifications: The system promptly sends contractor audit report notifications, effectively reducing risks and penalties caused by overdue improvements.

- Embedding Audit Standards: Incorporate audit standards into the system architecture to ensure safety inspections meet established criteria.

- Streamlined Report Generation: Solve the time-consuming manual consolidation of audit reports by using smart handheld devices for one-step report creation, saving time and effort.

- Data Integrity Enhancement: Improve record security by using handheld devices for data input, mitigating the risk of unauthorized alterations.

- Statistical Report Generation via Information System: Utilize the information system to generate management reports, reducing errors associated with paper-based and manual processes and enhancing report credibility.

- Mobile Safety Audit Management System: Comprising a front end mobile device module (compatible with Android smartphones, tablets, Windows tablets, and web browsers), back end management module, query operations, and electronic signature support.

- Provides 1 Sample Template: Offers a sample template for contractor entry management procedures or self-inspection forms for construction industry units.

- Offers 7 Standard Report Templates.

- Hardware Requirements: Server (DMZ) or cloud-based infrastructure, personal computers, Android smartphones and tablets, and Windows tablets.

- Optional Add-Ons: BI module, front end mobile device module (compatible with iOS).

Relevant companies or units that comply with the Occupational Safety and Health Act, including industries such as petrochemicals, construction, healthcare institutions, and schools from high school level and above.