Operational items

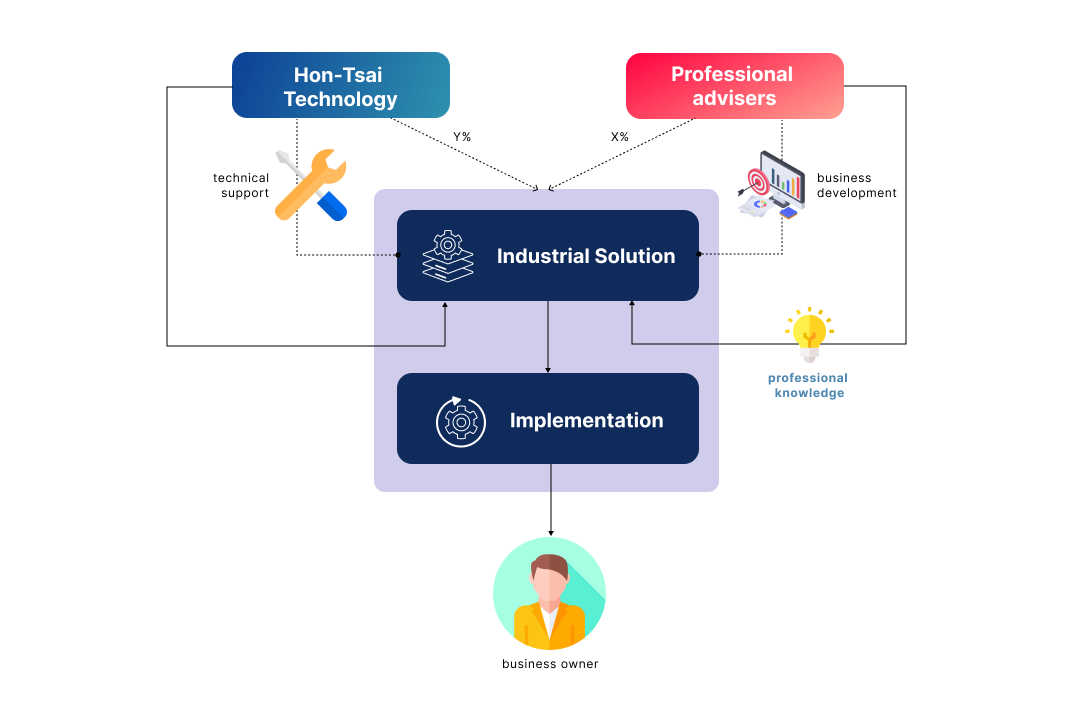

Until the end of 2016, Hon-Tsai Technology had successfully developed four safety management solutions: electronic inspection, occupational safety audit, equipment maintenance, and contractor management. These solutions further evolved into the following sales products in line with the trends of Industry 4.0 and the Internet of Things: mobile inspection management, long-distance pipeline inspection, security patrol system, intelligent preventive maintenance and inspection, automatic (primary) inspection management, occupational safety and quality inspection, contractor access management, mobile work permits, and smart elderly care platforms.

Inspection Management

Equipment Maintenance

Contractor Management

Work Safety Audit

3D Mapping Platform

Secure Internet of Things

Software Development

Mobile Device

Communication Technology

Integration of Technologies

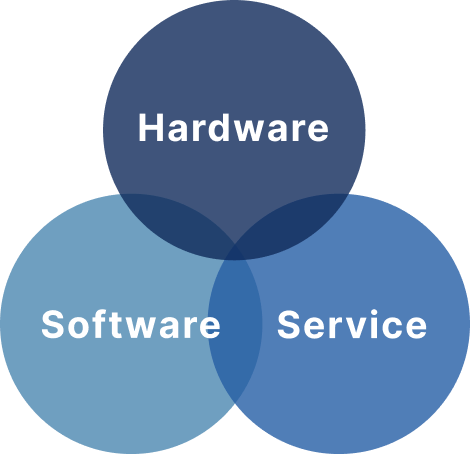

All of these products use the same technology and revolve around the same concept, which is the integration of software, mobile devices (such as tablets and smartphones), wireless communication technologies (such as RFID, NFC, 4G/5G, Wi-Fi, GPS, UWB, Lo-Ra), and information and communication technology (ICT), as well as the concept of the Internet of Things (IoT). These products are primarily used in the context of industrial safety. Therefore, from another perspective, it can be said that the company uses ICT technology and the Internet of Things to provide solutions to enterprises in industrial safety, helping them address specific challenges they face.

Corporate Vision

Because of the convenience of mobile communications and the popularization of the Internet of Things and mobile technologies Changing every field of the future. Hong-sai Technology Co., Ltd. pays equal attention to hardware. Software and Services. We use IT systems to enhance security company and develop a plan to audit each characteristic Safety production system.